Dijkman PACT

Interim Q-HSE management

- Build your Q-HSE team

- Determine your Q-HSE strategy and take the first steps

- Improve your Q-HSE performance

- Secure long term effectiveness

2

Project HSE management

- Build your HSE site team

- Get all (sub)contractors aligned

- Improve your HSE performance

3

Project HSE engineering

Integrate your HSE ambitions into all steps of your construction project:

- HSE in design: HazOp, SIL, LOPA, FMEA, HSE design standards, HSE plan design stage

- HSE during construction: HSE plan construction stage, HSE representation on site, HSE site audits, compliance monitoring

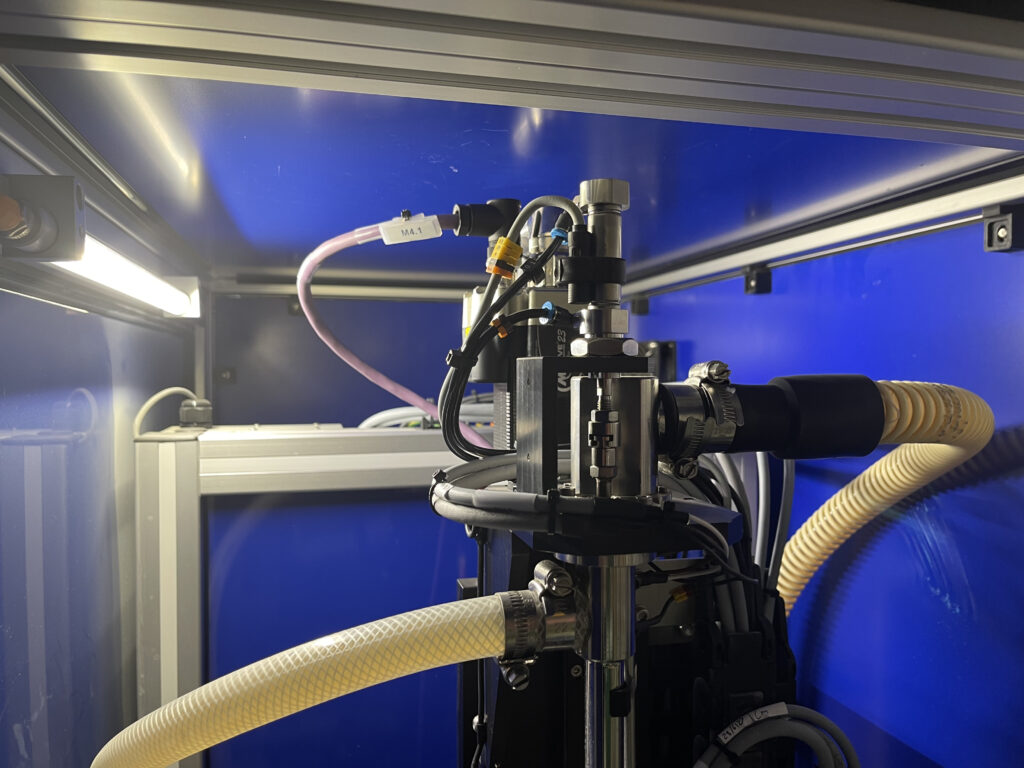

- Commissioning and qualification: commissioning of safety systems, safety during commissioning

- Transfer and start of use: HSE transfer documentation, PSSR

4

Q-HSE Improvement projects

- Q: Align CtQ -> QA -> QC

- Q: Improve performance based on statistical process control (SPC)

- H: Map, register, and limit exposure to hazardous chemicals (Chemrade, Toxic)

- S: Process safety studies, machinery safety inventories, implementation of improvements

- S: CE marking

- E: Permit compliance, improve relations with authorities

- Q-HSE: culture analysis and development

- Q-HSE: What is on your wish list?

Please contact:

Drs. Harmen Dijkman

+31 (0)6 4020 8790

harmen@dijkmanpact.com

KvK 53489209

BTW NL0014942922B21